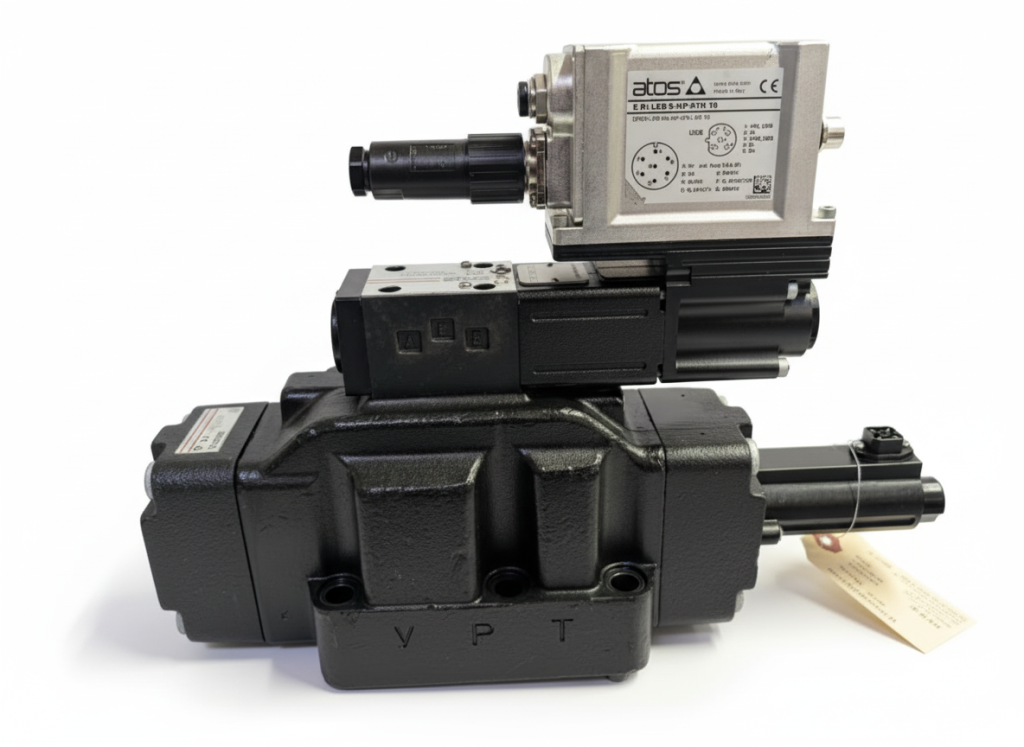

ATOS-DLKZ0TE140L7112

Looking for a reliable fix for your broken ATOS DLKZ0TE140L7112? NC Servo Tech is your trusted partner for expert diagnostics and high-quality repairs.

General Information

Whether the issue is age, wear, or contamination, the ATOS DLKZ0TE140L7112 can often be fully restored to optimal function. NC Servo applies the same structured approach to every rebuild.

Trusted By Professionals

NC Servo is a dedicated repair facility specializing in both valves and electronic controls. This allows us to operate without the delays and constraints of OEM service centers.

Frequently Asked Questions

We can prioritize urgent jobs when possible, just note it when submitting your repair request.

Our process always begins with a thorough troubleshooting and root-cause analysis to ensure we fix the problem correctly.

Most repairs are completed within 1 to 3 weeks, depending on workload and parts availability.

Yes. Our technicians can often identify units based on photos, dimensions, or manufacturer markings. You can upload a photo before shipping to speed up the process.

Yes, our repairs include our standard 1-year parts and labor warranty on parts and labor.

How We Rebuild This Valve

Each valve undergoes a complete teardown process to expose wear patterns and buildup. After cleaning every surface thoroughly, we replace damaged parts and reassemble the unit to exact specifications.

- Meticulous Cleaning: All parts undergo an ultrasonic cleaning process to remove contaminants before inspection.

- Comprehensive Teardown: Every valve is fully disassembled for a thorough internal inspection.

- Rigorous Testing: The reassembled unit undergoes rigorous leak and pressure testing to verify it performs to specification.

- Thorough Decontamination: Every component is put through a deep cleaning process to remove grime and buildup.

Testing & Diagnostics

With our 13-stand test facility and a Hagenbush proportional valve system, we verify flow curves, hysteresis, frequency response, and more. On request, comprehensive performance reports and graphs are available for purchase. Our operational testing ensures guaranteed reliability.

Performance Specifications

We ensure your ATOS DLKZ0TE140L7112 operates flawlessly under real-world conditions. Our diagnostics verify performance in real-world conditions, ensuring long-term reliability. Comprehensive Cycle life data and Performance data are available for purchase upon request.

Your Service & Logistics Partner

As a top specialist for ATOS DLKZ0TE140L7112 services, NC Servo ensures quick resolution with typical lead times of 2 to 3 weeks. Benefit from our 24/7 technical support to keep your systems running smoothly.

Comprehensive Product Data

For comprehensive insights into your ATOS DLKZ0TE140L7112, we can provide access to repair records and service logs. This transparency offers you record-keeping and aids in long-term maintenance planning.

Maintenance Tips

- Keep hydraulic fluid clean and at proper levels for consistent valve operation.

- Inspect ATOS DLKZ0TE140L7112 seals regularly to prevent leaks and ensure optimal performance.

- Conduct thorough visual inspections for wear or leaks during routine maintenance.

Start Your ATOS DLKZ0TE140L7112 Reconditioning Process

Trust NC Servo for industry-leading service. Contact us today to start your repair and get your unit maintained.