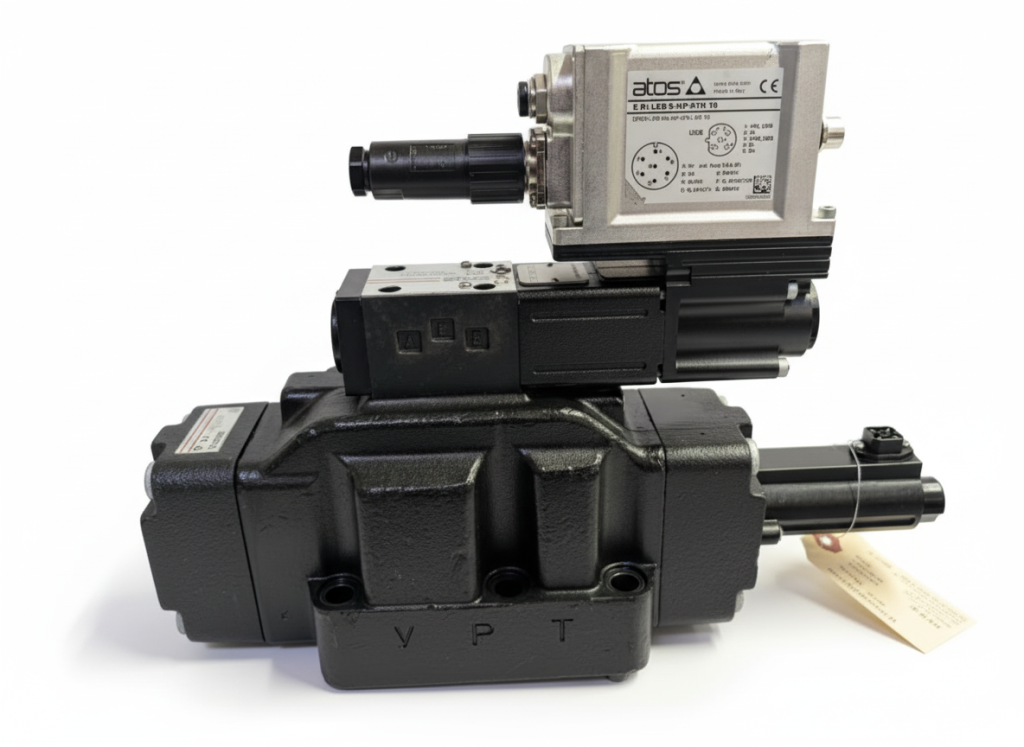

ATOS-DHRZ0-P5-012125/611

When your ATOS DHRZ0-P5-012125/611 valve fails, production stops. NC Servo Tech offers expert repair services to get your operations back online quickly, minimizing costly downtime.

Our Process Steps

Each ATOS DHRZ0-P5-012125/611 undergoes a meticulous reconditioning, starting with a full disassembly and ending with rigorous performance testing.

Key Details

Whether the issue is age, wear, or contamination, the ATOS DHRZ0-P5-012125/611 can often be fully restored to optimal function. NC Servo Tech applies the same structured approach to every rebuild.

Frequently Asked Questions

Yes, we offer rush service for critical repairs. Just let us know your deadline when submitting your request.

Many units can be restored to full function with quality parts and testing. If the main housing or board is intact, it’s usually worth it.

Yes. Our technicians can often identify units based on photos, dimensions, or manufacturer markings. You can upload a photo before shipping to speed up the process.

We’ll clean it during our process, but sending it in reasonably clean reduces handling time.

If a unit is beyond repair, we’ll provide a return or replacement recommendation.

What Sets Us Apart

We’ve got the parts and the experience. We’re built to move fast, restoring most units with stocked components to avoid lengthy delays.

Specializing in ATOS DHRZ0-P5-012125/611 servo valve technology for over three decades

Repair Process

The comprehensive repair process for the ATOS DHRZ0-P5-012125/611 includes full disassembly, diagnostic review, and replacement of failed seals, spools, or other critical elements. Final assembly includes thorough leak and function testing.

- Thorough Decontamination: Every component is put through a deep cleaning process to remove grime and buildup.

- Rigorous Testing: The reassembled unit undergoes rigorous leak and pressure testing to verify it performs to specification.

- Final Performance Verification: After reassembly, each valve is bench-tested to ensure it meets or exceeds original performance specifications.

- Meticulous Cleaning: All parts undergo an ultrasonic cleaning process to remove contaminants before inspection.

Our Testing Process

NC Servo Tech operates thirteen state-of-the-art test stands, including specialized setups specifically designed for proportional and servo valves. Every valve goes through comprehensive performance and leak testing using industry-standard fluids including MIL-5606 and Skydrol. Our functional testing ensures guaranteed reliability.

Advanced Technical Details

We ensure your ATOS DHRZ0-P5-012125/611 operates flawlessly under real-world conditions. Our diagnostics verify performance in real-world conditions, ensuring long-term reliability. Comprehensive Cycle life data and Performance data are available for purchase upon request.

Beyond Repair: Complete Solutions

Beyond standard maintenance, we offer specialized repairs for your ATOS DHRZ0-P5-012125/611 unit. Our disassembly process meticulously involves actions such as overhaul and recondition, and uses only premium replacement components, ensuring a lasting fix.

Maintenance Tips

- Conduct thorough visual inspections for wear or leaks during routine maintenance.

- Keep hydraulic fluid clean and at proper levels for consistent valve operation.

- Replace inline filters according to maintenance schedules to maintain proper flow rates.

Get an Expert Repair for Your ATOS DHRZ0-P5-012125/611

Trust NC Servo Tech for exceptional service. Contact us today to schedule your repair and get your unit serviced.