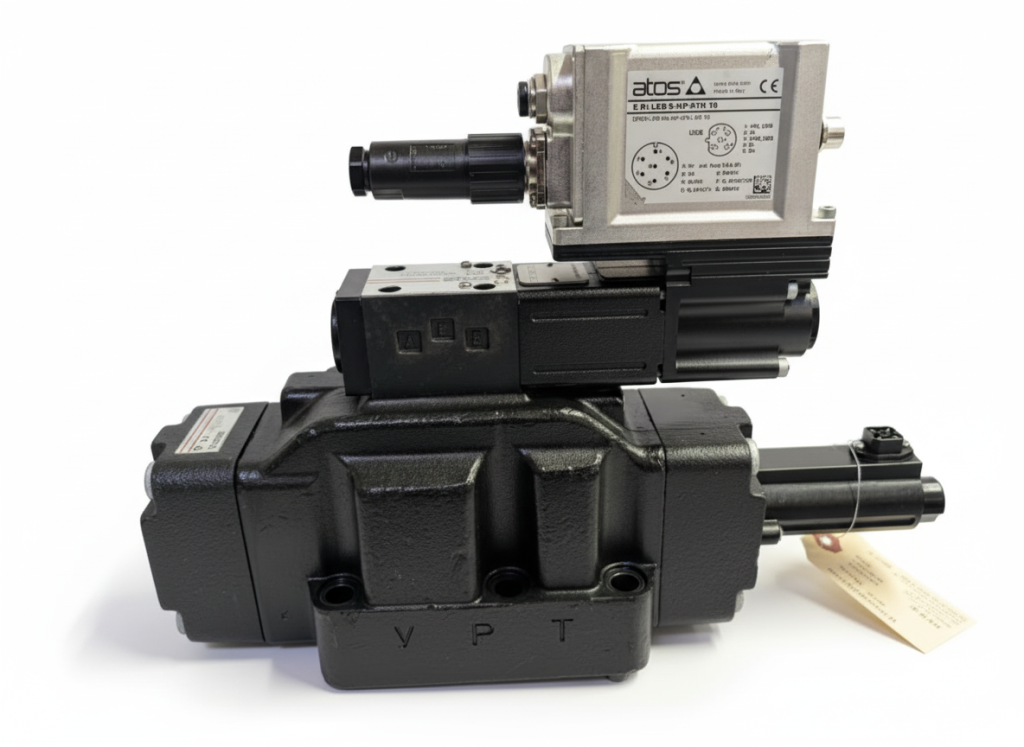

ATOS-C0/10-9-32/22X70-H308-22

Looking for a reliable fix for your broken ATOS C0/10-9-32/22X70-H308-22? NC Servo Tech is your trusted partner for expert diagnostics and high-quality repairs.

About This Valve

The ATOS C0/10-9-32/22X70-H308-22 is one of many models we routinely service with expertise. Our comprehensive process includes full disassembly, thorough cleaning, and precise reassembly using reliable components.

Trusted By Professionals

We’ve got the parts and the experience you need. We’re built to move fast, restoring most units with stocked components to avoid lengthy delays.

Specializing in ATOS C0/10-9-32/22X70-H308-22 servo valve technology for over three decades

Frequently Asked Questions

Yes. We perform diagnostic testing and provide an assessment before moving forward.

Yes. Our repairs include a full one-year warranty.

We’ll always confirm next steps if a unit can’t be rebuilt.

In most cases, repairs cost less than replacements, especially for legacy or OEM-specific models. We’ll evaluate yours and let you know if it’s economically viable.

Standard turnaround is 1-3 weeks, with expedited options available.

Repair Process

We rebuild every valve from the inside out, starting with detailed cleaning and inspection, followed by new parts installation, careful reassembly, and rigorous bench testing.

- Meticulous Cleaning: All parts undergo an ultrasonic cleaning process to remove contaminants before inspection.

- Rigorous Testing: The reassembled unit undergoes rigorous leak and pressure testing to verify it performs to specification.

- In-House Parts Sourcing: Many repairs use reliable components sourced from our extensive inventory of existing units.

- Thorough Decontamination: Every component is put through a deep cleaning process to remove grime and buildup.

Testing & Diagnostics

We carry out full diagnostics, including flow gain, leakage, pressure shift, and frequency testing, on every valve. Our test facility supports detailed performance logging and report generation for quality assurance. Our pre-shipment testing ensures optimal functionality.

Full-Spectrum ATOS C0/10-9-32/22X70-H308-22 Care

Beyond standard maintenance, we offer specialized reconditioning for your ATOS C0/10-9-32/22X70-H308-22 unit. Our teardown process meticulously involves actions such as refurbishment and validate, and uses only premium replacement components, ensuring a lasting fix.

Seamless Support for Your Operations

As a leading source for ATOS C0/10-9-32/22X70-H308-22 services, NC Servo Tech ensures quick resolution with typical lead times of 1 to 3 weeks. Benefit from our dedicated support team to keep your systems running smoothly.

Understanding Your Unit: Data & Insights

For detailed insights into your ATOS C0/10-9-32/22X70-H308-22, we can provide access to service logs and repair records. This transparency offers you compliance assurance and aids in long-term maintenance planning.

Maintenance Tips

- Check valve alignment carefully to prevent undue stress on internal components.

- Perform comprehensive fluid analysis to detect contamination early and prevent system damage.

- Keep hydraulic fluid clean and at proper levels for consistent valve operation.

Request a Quote for Your ATOS C0/10-9-32/22X70-H308-22 Maintenance

Trust NC Servo Tech for industry-leading service. Contact us today to initiate your repair and get your unit maintained.