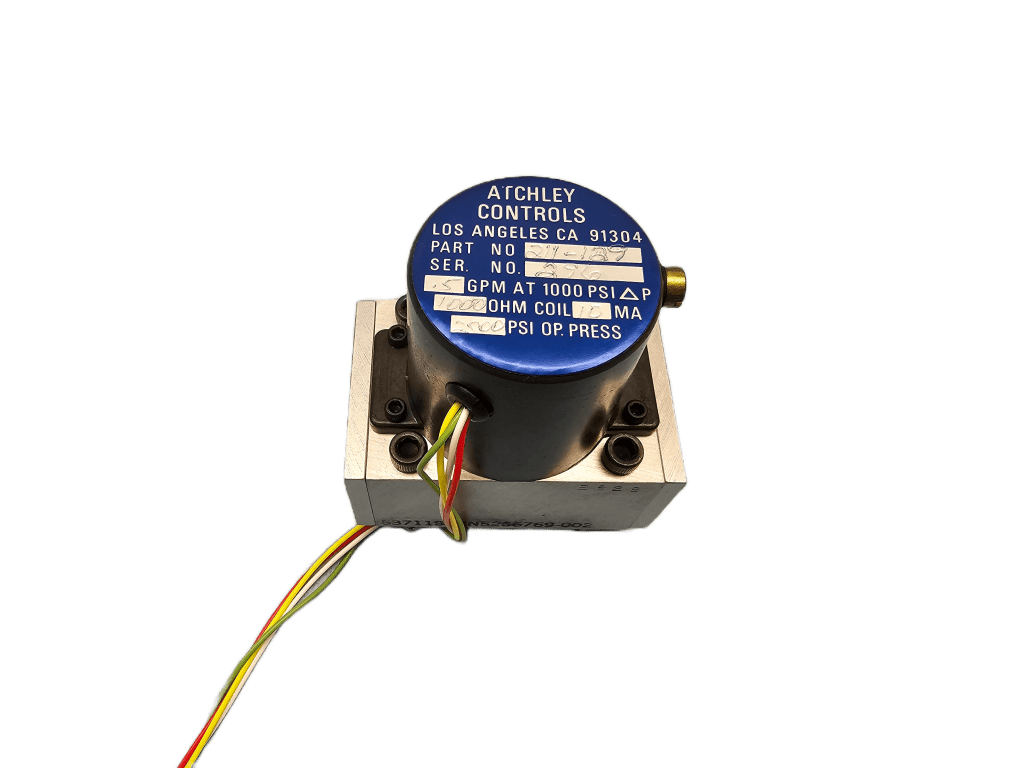

ATCHLEY-231-131

A broken ATCHLEY 231-131 valve can disrupt your entire system. We provide fast, reliable repairs and have units in stock to get you back up and running.

Overview

We handle a wide range of ATCHLEY 231-131 units with care and consistency. Each unit receives detailed inspection, internal cleaning, and full reconditioning.

What Sets Us Apart

We’ve built our shop around one thing: industrial repair. With decades of experience and deep product knowledge, we deliver consistent results, one unit at a time.

30+ years of expertise in ATCHLEY 231-131 Valve Repair

Frequently Asked Questions

We stand behind our work completely. Warranty terms vary by unit but are included with our standard 1-year parts and labor warranty.

Yes, we perform comprehensive diagnostic testing and provide an assessment before moving forward with repairs.

Absolutely. Even if the tag is worn off, we can match the unit based on shape, size, and performance specs.

Most repairs are completed within 1 to 3 weeks, depending on current workload and parts availability.

We’ll give you an honest assessment. If a repair doesn’t make sense, we’ll recommend alternatives, no pressure.

Service Procedure

Once a valve arrives, we tear it down fully, examine key surfaces, and replace worn or damaged parts using components we already have on hand, avoiding the long delays you’d get from OEM suppliers.

- Final Performance Verification: After reassembly, each valve is bench-tested to ensure it meets or exceeds original performance specifications.

- Rigorous Testing: The reassembled unit undergoes rigorous leak and pressure testing to verify it performs to specification.

- Comprehensive Teardown: Every valve is fully disassembled for a thorough internal inspection.

- Thorough Decontamination: Every component is put through a deep cleaning process to remove grime and buildup.

Testing & Diagnostics

We carry out complete diagnostics, including flow gain, leakage, pressure shift, and frequency testing, on every valve. Our test facility supports detailed performance logging and comprehensive report generation for quality assurance. Our performance testing ensures optimal functionality.

Our Industry Reach

Our professional repair services for the ATCHLEY 231-131 are trusted across various critical sectors, including Manufacturing, Construction, and Defense. We understand the unique demands of valves in these environments.

Fast Turnaround & Dedicated Support

As a leading source for ATCHLEY 231-131 services, NC Servo Technology ensures quick resolution with typical lead times of 1 to 2 weeks. Benefit from our expert assistance to keep your systems running smoothly.

Detailed Documentation Available

For comprehensive insights into your ATCHLEY 231-131, we can provide access to reports and service logs. This transparency offers you peace of mind and aids in long-term maintenance planning.

Maintenance Tips

- Monitor operating temperatures to identify potential issues before failure occurs.

- Perform comprehensive fluid analysis to detect contamination early and prevent system damage.

- Document all maintenance activities to track performance trends over time.

Schedule Your ATCHLEY 231-131 Service Today

Trust NC Servo Technology for industry-leading service. Contact us today to initiate your repair and get your unit serviced.