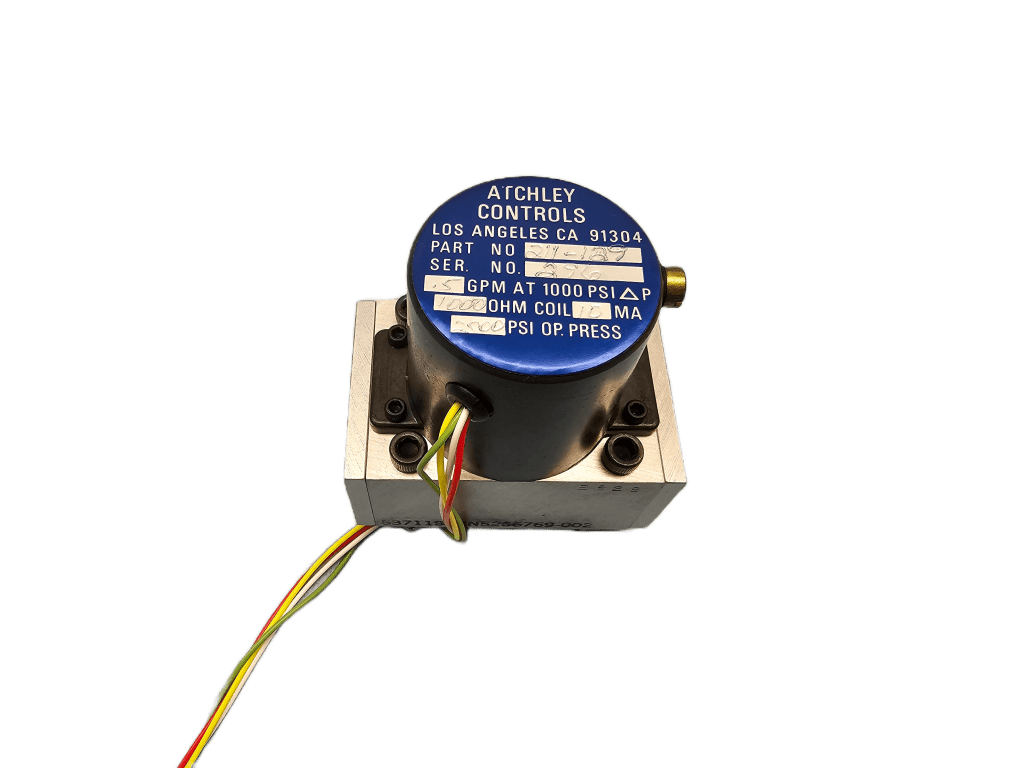

ATCHLEY-225A-131

A broken ATCHLEY 225A-131 valve can disrupt your entire system. We provide fast, reliable repairs and have units in stock to get you back up and running.

Our Approach to Repair

Our comprehensive repair process for the ATCHLEY 225A-131 begins with a full teardown and ultrasonic cleaning to assess all components.

What Sets Us Apart

As a focused electronic controls company, our technicians work on industrial components like the ATCHLEY 225A-131 daily, giving us a level of experience you won’t find elsewhere.

30+ years of expertise in ATCHLEY 225A-131 Valve Repair

Frequently Asked Questions

You don’t have to clean it, but removing excess oil or debris helps us get started faster.

Every unit goes through thorough inspection to identify the root cause of the issue before we begin work.

We’ll always confirm next steps if a unit can’t be rebuilt to functional specifications.

We recommend sending pictures, especially if the model number is unclear or there is visible wear.

We can prioritize urgent jobs when possible, just note it when submitting your repair request.

Service Procedure

Each valve goes through a full teardown to expose wear and buildup. After cleaning every surface, we replace damaged parts and reassemble the unit to spec.

- Final Performance Verification: After reassembly, each valve is bench-tested to ensure it meets or exceeds original performance specifications.

- Rigorous Testing: The reassembled unit undergoes rigorous leak and pressure testing to verify it performs to specification.

- Meticulous Cleaning: All parts undergo an ultrasonic cleaning process to remove contaminants before inspection.

- In-House Parts Sourcing: Many repairs use reliable components sourced from our extensive inventory of existing units.

Testing & Diagnostics

With over a dozen dedicated flow test stands and a Hagenbush proportional valve system, we verify flow curves, hysteresis, frequency response, and additional critical parameters. On request, comprehensive performance reports and detailed graphs are available for purchase. Our pre-shipment testing ensures consistent performance.

Beyond Repair: Complete Solutions

Beyond standard maintenance, we offer specialized repairs for your ATCHLEY 225A-131 unit. Our overhaul process meticulously involves actions such as expose and reassemble, and uses only high-quality replacement components, ensuring a lasting fix.

Maintenance Tips

- Keep hydraulic fluid clean and at proper levels for consistent valve operation.

- Conduct thorough visual inspections for wear or leaks during routine maintenance.

- Document all maintenance activities to track performance trends over time.

Start Your ATCHLEY 225A-131 Reconditioning Process

Trust NC Servo for top-tier service. Contact us today to start your repair and get your unit maintained.