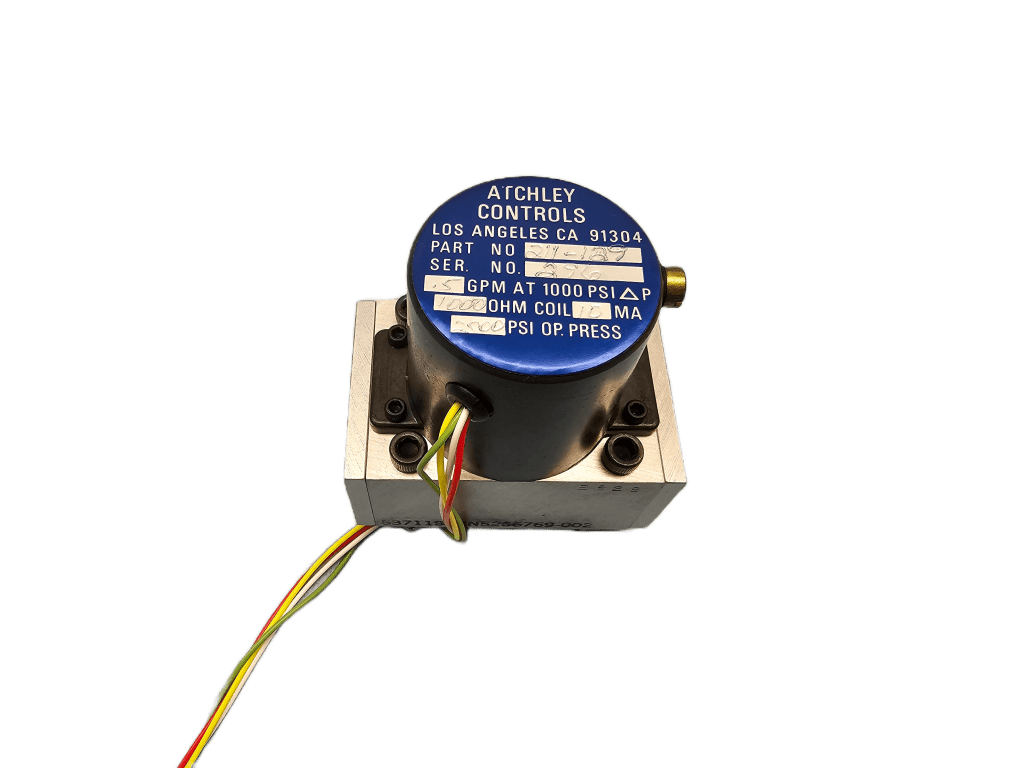

ATCHLEY-215A-400

When your ATCHLEY 215A-400 valve fails, production stops. NC Servo Tech offers expert repair services to get your operations back online quickly, minimizing costly downtime.

How We Service Your Unit

We specialize in the complete overhaul of your ATCHLEY 215A-400, including the replacement of all necessary gaskets and worn components.

Why Work With Us

Unlike OEM service centers, we use our own inventory to handle most rebuilds. That cuts down on downtime and helps you get back up and running sooner.

Frequently Asked Questions

We can prioritize urgent jobs when possible, just note it when submitting your repair request.

We stand behind our work completely. Warranty terms vary by unit but are included with a comprehensive 12-month warranty.

Turnaround time varies by model, but we aim to complete most jobs within 10-15 business days.

Part of our intake includes troubleshooting and root-cause analysis.

We’ll always confirm next steps if a unit can’t be rebuilt to functional specifications.

Repair Process

The comprehensive repair process for the ATCHLEY 215A-400 includes full disassembly, diagnostic review, and replacement of failed seals, spools, or other critical elements. Final assembly includes thorough leak and function testing.

- In-House Parts Sourcing: Many repairs use reliable components sourced from our extensive inventory of existing units.

- Complete Disassembly: The unit is fully disassembled, and all parts are laid out for individual inspection.

- Thorough Decontamination: Every component is put through a deep cleaning process to remove grime and buildup.

- Meticulous Cleaning: All parts undergo an ultrasonic cleaning process to remove contaminants before inspection.

Testing & Diagnostics

We carry out complete diagnostics, including flow gain, leakage, pressure shift, and frequency testing, on every valve. Our test facility supports detailed performance logging and comprehensive report generation for quality assurance. Our functional testing ensures consistent performance.

Industries We Serve

Our trusted repair services for the ATCHLEY 215A-400 are trusted across various critical sectors, including Marine, Industrial Machinery, and Aerospace. We understand the unique demands of valves in these environments.

Fast Turnaround & Dedicated Support

As a leading source for ATCHLEY 215A-400 services, NC Servo Technology ensures quick resolution with typical lead times of 1 to 2 weeks. Benefit from our 24/7 technical support to keep your systems running smoothly.

Maintenance Tips

- Check valve alignment carefully to prevent undue stress on internal components.

- Keep hydraulic fluid clean and at proper levels for consistent valve operation.

- Perform comprehensive fluid analysis to detect contamination early and prevent system damage.

Get an Expert Repair for Your ATCHLEY 215A-400

Trust NC Servo Technology for top-tier service. Contact us today to start your repair and get your unit reconditioned.