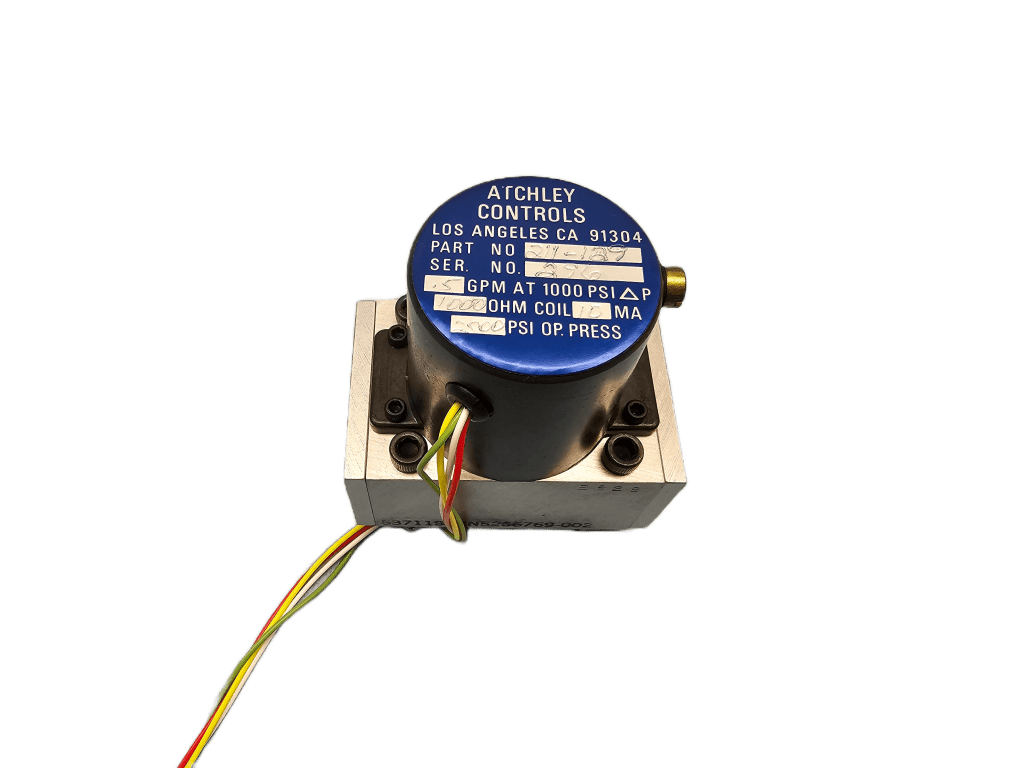

ATCHLEY-215A-242

Reliable Services for your ATCHLEY 215A-242. We offer cost-effective solutions. Inquire today!

Product Snapshot

NC Servo Technology provides repair and reconditioning for the ATCHLEY 215A-242. With our in-house tools and consistent methods, we return each unit to reliable performance.

The NC Servo Tech Advantage

NC Servo Technology operates independently, so we’re not tied to manufacturer delays or restrictions. That means more flexibility when your system is down.

30+ years of expertise in ATCHLEY 215A-242 Valve Repair

Frequently Asked Questions

We regularly work on unidentified units. Just send us a few detailed images and any visible part numbers, and we’ll take it from there.

Definitely. Photos let us start the ID process and ensure faster processing once the unit arrives.

Our process always begins with a thorough troubleshooting and root-cause analysis to ensure we fix the problem correctly.

Yes, we offer rush service for critical repairs. Just let us know your deadline.

Please send the unit as it is. Our technicians will perform a full cleaning and decontamination before starting the repair process.

How We Rebuild This Valve

Our team completely disassembles each valve to assess internal wear. After ultrasonic cleaning, we install high-grade replacements and reassemble to exacting standards.

- Thorough Decontamination: Every component is put through a deep cleaning process to remove grime and buildup.

- Meticulous Cleaning: All parts undergo an ultrasonic cleaning process to remove contaminants before inspection.

- In-House Parts Sourcing: Many repairs use reliable components sourced from our extensive inventory of existing units.

- Rigorous Testing: The reassembled unit undergoes rigorous leak and pressure testing to verify it performs to specification.

Quality Check Procedures

With over a dozen dedicated flow test stands and a Hagenbush proportional valve system, we verify flow curves, hysteresis, frequency response, and more. On request, comprehensive performance reports and graphs are available for purchase. Our functional testing ensures consistent performance.

Full-Spectrum ATCHLEY 215A-242 Care

Beyond standard sales, we offer specialized overhauls for your ATCHLEY 215A-242 unit. Our overhaul process meticulously involves actions such as repair and reassemble, and uses only premium replacement components, ensuring a lasting fix.

Ready When You Are

With an extensive stock of 17,000+ valves, we are often able to provide immediate solutions, minimizing your downtime.

Maintenance Tips

- Keep hydraulic fluid clean and at proper levels for consistent valve operation.

- Document all maintenance activities to track performance trends over time.

- Perform comprehensive fluid analysis to detect contamination early and prevent system damage.

Request a Quote for Your ATCHLEY 215A-242 Maintenance

Trust NC Servo Technology for superior service. Contact us today to initiate your repair and get your unit serviced.