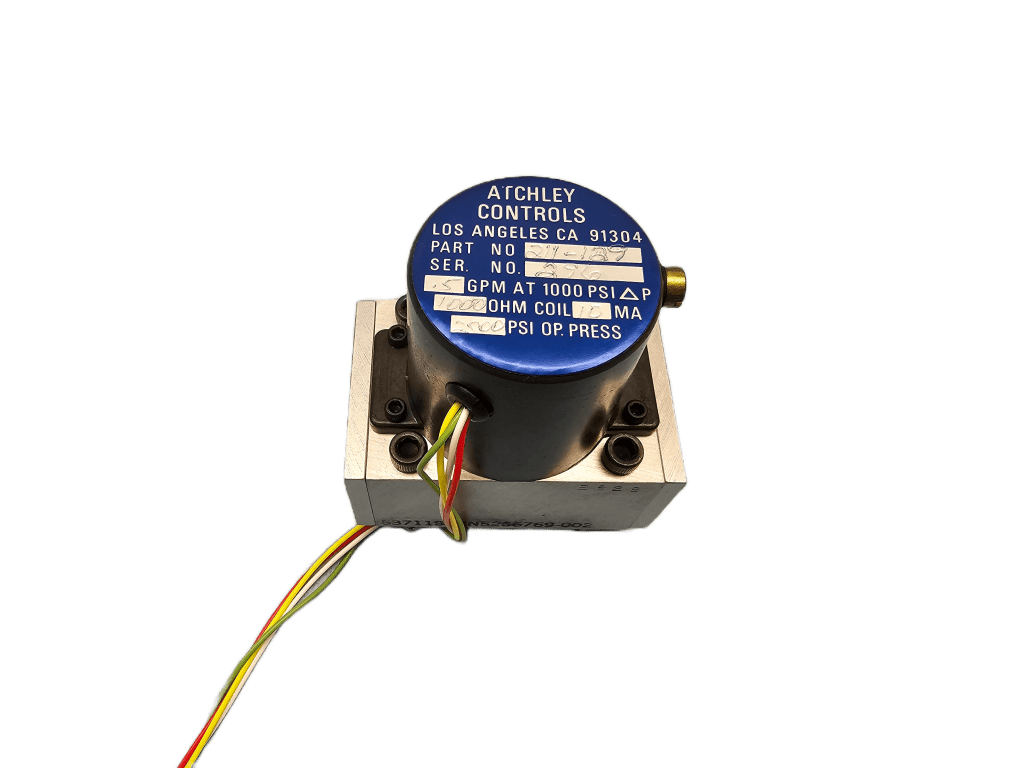

ATCHLEY-211A-769A

Looking for a reliable fix for your broken ATCHLEY 211A-769A? NC Servo Tech is your trusted partner for expert diagnostics and high-quality repairs.

Key Details

We handle a wide range of ATCHLEY 211A-769A units with care and consistency. Each unit receives detailed inspection, internal cleaning, and full reconditioning.

What Sets Us Apart

We’ve got the parts and the experience. We’re built to move fast, restoring most units with stocked components to avoid lengthy delays.

Frequently Asked Questions

Yes, we offer rush service for critical repairs. Just let us know your deadline when submitting your request.

If a unit is beyond repair, we’ll provide a detailed explanation and can recommend a replacement.

Yes, our repairs include a comprehensive 12-month warranty on parts and labor.

You can send your unit to us as-is. We will handle all the necessary cleaning and preparation as part of our standard service.

Turnaround time varies by model, but we aim to complete most jobs within 10-15 business days.

Valve Refurbishment Steps

Our team completely disassembles each valve to assess internal wear. After ultrasonic cleaning, we install high-grade replacements and reassemble to exacting standards.

- Meticulous Cleaning: All parts undergo an ultrasonic cleaning process to remove contaminants before inspection.

- Rigorous Testing: The reassembled unit undergoes rigorous leak and pressure testing to verify it performs to specification.

- In-House Parts Sourcing: Many repairs use reliable components sourced from our extensive inventory of existing units.

- Complete Disassembly: The unit is fully disassembled, and all parts are laid out for individual inspection.

Testing & Diagnostics

With our 13-stand test facility and a Hagenbush proportional valve system, we verify flow curves, hysteresis, frequency response, and additional critical parameters. On request, comprehensive performance reports and detailed graphs are available for purchase. Our functional testing ensures optimal functionality.

Industries We Serve

Our trusted repair services for the ATCHLEY 211A-769A are trusted across various critical sectors, including Power Generation, Industrial Machinery, and Construction. We understand the unique demands of valves in these environments.

Technical Insights

We ensure your ATCHLEY 211A-769A operates flawlessly under real-world conditions. Our diagnostics verify performance in real-world conditions, ensuring long-term reliability. Comprehensive Specification sheets and Performance data are available for purchase upon request.

Seamless Support for Your Operations

As a leading source for ATCHLEY 211A-769A services, NC Servo ensures quick resolution with typical lead times of 1 to 2 weeks. Benefit from our expert assistance to keep your systems running smoothly.

Ready When You Are

With more than 17,000 valve units in inventory, we are often able to provide immediate solutions, minimizing your downtime.

Maintenance Tips

- Check valve alignment carefully to prevent undue stress on internal components.

- Monitor operating temperatures to identify potential issues before failure occurs.

- Inspect ATCHLEY 211A-769A seals regularly to prevent leaks and ensure optimal performance.

Start Your ATCHLEY 211A-769A Reconditioning Process

Trust NC Servo for exceptional service. Contact us today to initiate your repair and get your unit maintained.