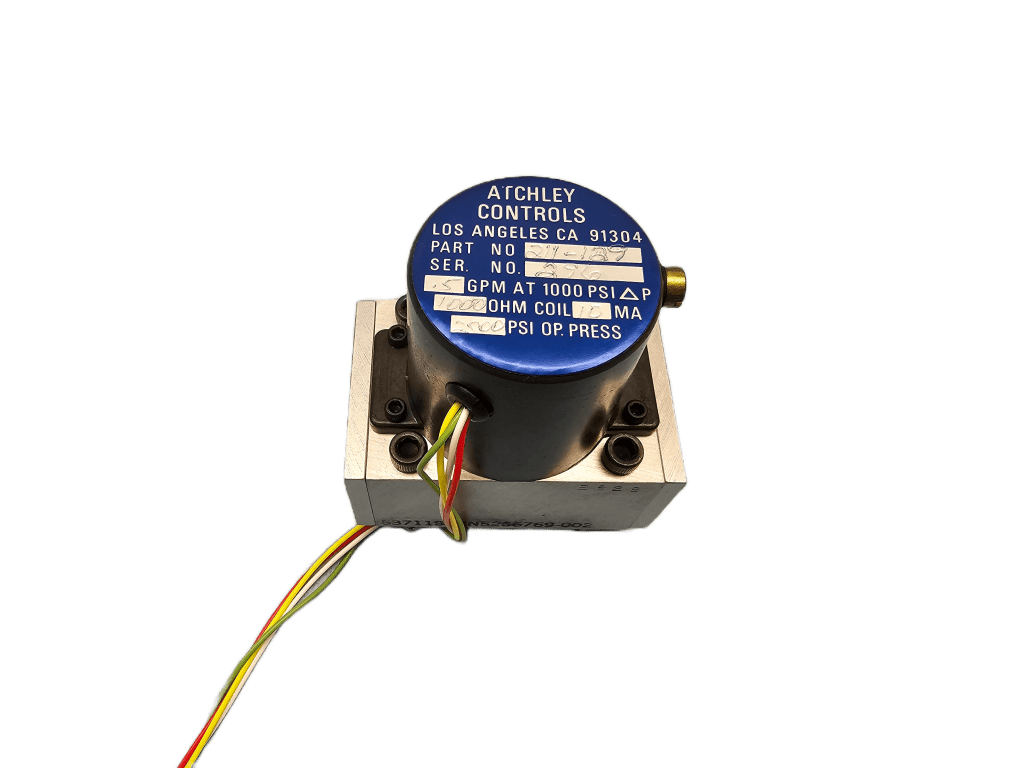

ATCHLEY-211A-169A

Precision Support for your ATCHLEY 211A-169A. We offer cost-effective solutions. Get a quote!

About This Valve

At NC Servo Technology, our shop is fully equipped to service the ATCHLEY 211A-169A professionally. We use a consistent, detailed process to ensure every unit is restored to reliable, peak performance.

Why Choose Us

As a specialized valve repair shop, we have the dedicated equipment and expertise that general-purpose shops lack, ensuring your component is serviced correctly the first first time.

Frequently Asked Questions

We’ll give you an honest assessment based on our experience. If a repair doesn’t make sense, we’ll recommend alternatives with no pressure.

Expedited options are available for an additional fee. Contact us to check current scheduling availability.

Yes. Our technicians can often identify units based on photos, dimensions, or manufacturer markings. You can upload a photo before shipping to speed up the process.

We stand behind our work completely. Warranty terms vary by unit but are included with a full one-year warranty.

Please send the unit as it is. Our technicians will perform a full cleaning and decontamination before starting the repair process.

Repair Process

The repair process for the ATCHLEY 211A-169A includes full disassembly, diagnostic review, and replacement of failed seals, spools, or other elements. Final assembly includes leak and function testing.

- Rigorous Testing: The reassembled unit undergoes rigorous leak and pressure testing to verify it performs to specification.

- Meticulous Cleaning: All parts undergo an ultrasonic cleaning process to remove contaminants before inspection.

- Final Performance Verification: After reassembly, each valve is bench-tested to ensure it meets or exceeds original performance specifications.

- Complete Disassembly: The unit is fully disassembled, and all parts are laid out for individual inspection.

Quality Check Procedures

With over a dozen dedicated flow test stands and a Hagenbush proportional valve system, we verify flow curves, hysteresis, frequency response, and more. On request, comprehensive performance reports and graphs are available for purchase. Our functional testing ensures guaranteed reliability.

Maintenance Tips

- Check valve alignment carefully to prevent undue stress on internal components.

- Document all maintenance activities to track performance trends over time.

- Perform comprehensive fluid analysis to detect contamination early and prevent system damage.

Start Your ATCHLEY 211A-169A Reconditioning Process

Trust NC Servo Technology for top-tier service. Contact us today to schedule your repair and get your unit repaired.